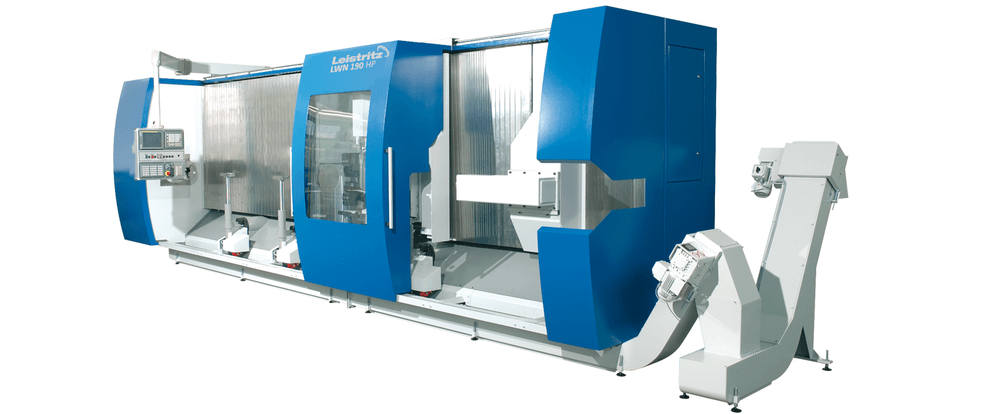

Precision Thread Whirling for Large-Scale Ball Screw Spindles

Engineered for high-performance machining, the LWN 190 whirling machine efficiently handles large ball screw spindles with diameters from 32 to 160 mm and ball sizes between 3.5 to 25 mm. Designed for demanding production needs, it offers flexibility with three available lengths—8, 10, and 12 meters—to meet diverse manufacturing requirements.

Built for Efficiency & Precision:

- Short whirling & setup times to maximize productivity

- Superior surface finishing for high-quality components

- Dry machining for a cleaner, more sustainable process

- Automatic chip conveyor for seamless material handling

Standard Features:

- Open machine construction for easy accessibility

- Integrated lighting for optimal visibility

- Manual chuck & centering steady rest for secure workholding

- Motorized tailstock with fixed tailstock center

- Z- and X-axis motor encoder positioning for precise movement

- FANUC 0i-TF machine controller for seamless operation

Optional Features for Enhanced Performance:

- Hydraulic power chuck & workpiece clamping for increased stability

- Network connectivity for smarter machining integration

- Tool wear detection for reliable, long-term performance