Oil wells assisted by ESP’s or sucker rod pumps tend to experience frequent or extended outages due to associated gas blocking the intake to plunger pumps and ESPs. If too much gas accumulates down-hole, the down-hole pump will simply shut down until enough gas passes up the annulus into the flow line and the liquid level is restored in the well. A typical method of assisting the gas flow through the annulus is to install a compressor. However, slugs of liquid tend to come up with the gas, which can overwhelm the compressor, resulting in damage, tripping their shutoff, and causing the down-hole pump to shut in production. A beam pump mounted cylinder for compression is an alternative solution to this problem but has limited ability to draw down the wellhead pressure and reduce their effectiveness.

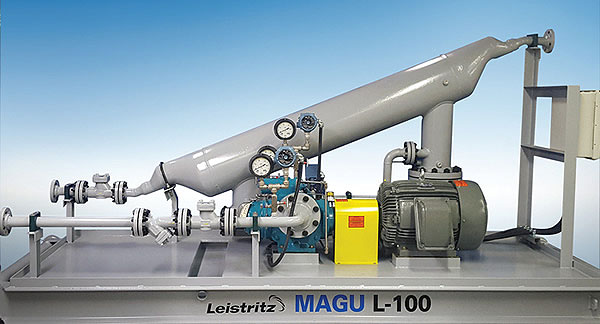

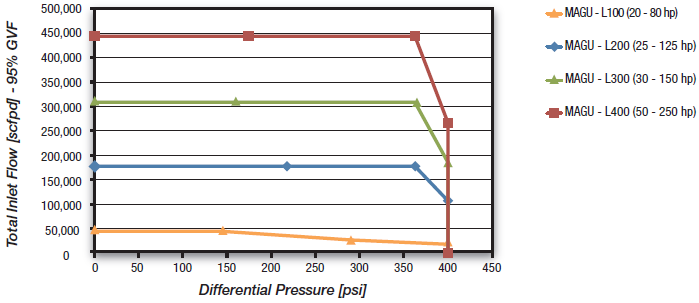

A practical and effective solution to boosting the associated gas is a Multiphase Annulus Gas Unit (MAGU). This self-contained unit efficiently boost gas and liquid coming up the annulus and boost the multiphase flow directly into the flow line back to the satellite or battery. By lowering the bottom hole pressure, substantially more liquids flow from the formation into the down-hole pump intake, the liquid level in the tubing allowing it to operate above the bubble point. Since the MAGU handles every phase from 100% gas to 100% liquid, it cannot be overwhelmed by any liquid. The MAGU is equipped with an optional speed control which assists better plateau production and greater production flexibility over the life of the well.

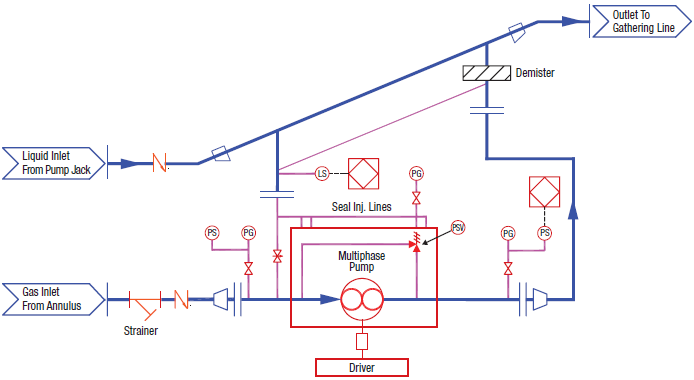

Each unit has two inlet connections. The first inlet connects to the production line coming off the wellhead. The liquid flow passes through a liquid knock-out boot, trapping a small amount of liquids for recirculating and priming the Multiphase Pump, while overflow continues on to the battery or gathering facility.

The second inlet connects to the annulus gas port and the gas flows to the Multiphase Pump suction. The recirculated stream of liquid from the liquid knock-out boot ensures the MPP remains primed and therefore able to pump 100% gas from the annulus. The MPP discharge line from the unit connects to the gathering or export line, downstream of the liquid knock-out boot.

MAGUs are typically mounted in an oil field or on a portable skid and can be moved easily from one well to another, or left in place to support single or multiple wells.