High-Speed Solutions for Helical Threads, Ball Screws, and Complex Components

Leistritz whirling machines are engineered to deliver exceptional precision in the production of complex components such as helical threads, ball screws, trapezoidal threads, and gear worms. These machines are a key asset in CNC machining and advanced industrial manufacturing, particularly in aerospace, automotive, and other sectors where high-performance parts are essential.

Whirling is a specialized process for producing intricate thread profiles. It involves an eccentrically positioned whirling ring that rotates around a slowly turning workpiece, effectively cutting away material without the need for coolant. This method ensures heat dissipation through the chips, preventing stress on the workpiece and allowing for precise, energy-efficient production. Leistritz machines are capable of both internal and external whirling, giving manufacturers the flexibility to produce complex internal thread profiles, such as those found in pump spindles, as well as external threads like lead screws and ball screws. This versatility makes them ideal for creating durable parts with superior surface finishes, used in precision manufacturing.

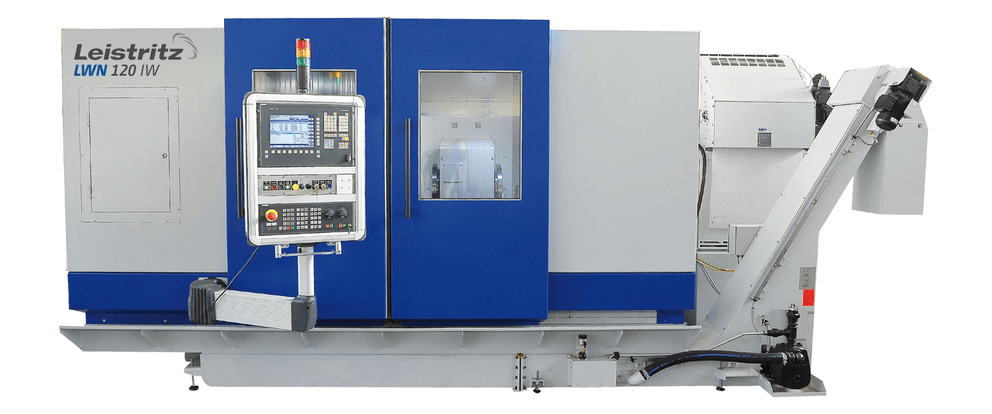

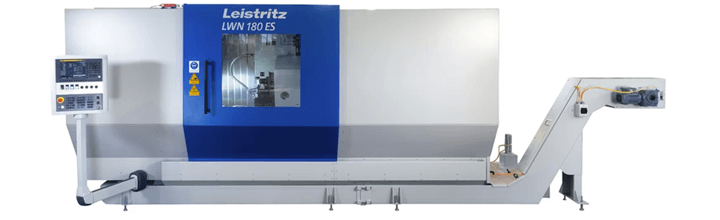

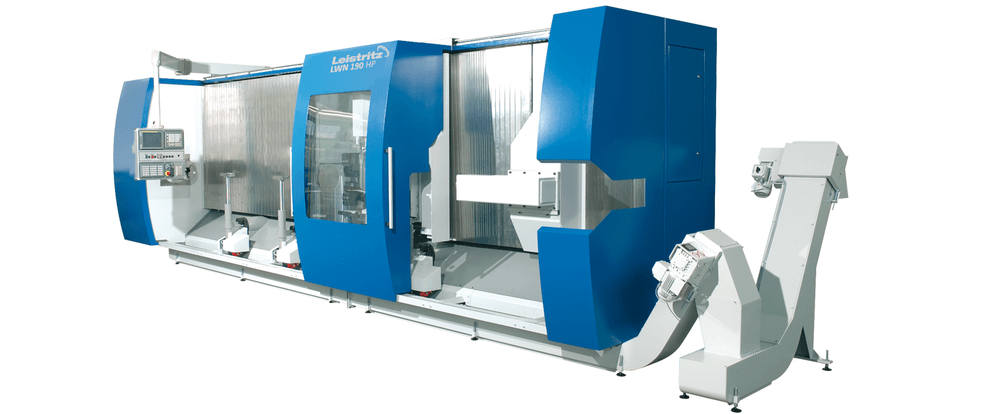

Leistritz’s LWN series are highly regarded for their ability to handle complex, large-scale manufacturing while maintaining energy efficiency. These machines are widely used for producing parts like ball screw spindles and gear worms, offering a cost-effective solution for companies aiming to streamline custom manufacturing processes with advanced CNC machining equipment.