What is Whirling?

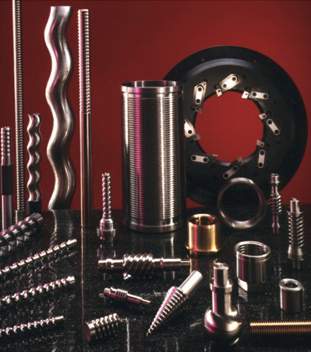

Whilring’s surface finish quality is comparable, if not better, to that of grinding. This is directly related to the longer insert-to-workpiece contact time, resulting in not only shorter but also fewer polyhedral peaks. The Leistritz easy-to-use tooling system combined with the benefits of whirling’s faster machining times and surface finish quality, clearly show that whirling is today’s most economical and cost effective solution to produce external threaded parts.

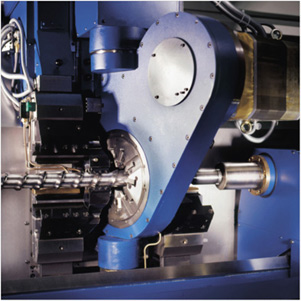

Whirling is a manufacturing operation in which “a geometrically oriented cut removes material. Whirling removes material similar to that of milling however, in whirling the cutter uses carbide inserts arranged along the inside circumference of a ring. A system developed by Leistritz AG of Germany utilizes a whirling ring with a predetermined cutting circle diameter calculated from the thread or worm data (OD, pitch and depth).

Whirling Makes Economic Sense!

- Elimination of expensive grinding operation

- Reduced cycle times, up to 3 times faste

- Precise pitch and thread profiles

- Rapid set-up and change over times

- Dry machining does away with costly cutting fluid

The Cutting Process and Chip Formation

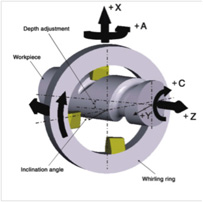

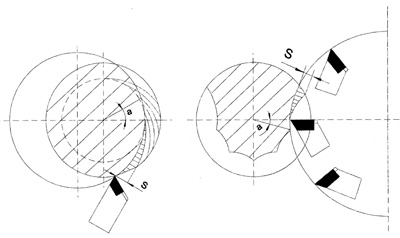

Cutting is the result of the whirling ring rotating at high speed around a slowly rotating workpiece "C axis". The rotation of the workpiece combined with advancement of the "Z axis" tool head, correspond to the thread pitch required (see figure 1).

The cutting angle of the tool head is controlled about "A axis" to correspond to the pitch angle of the thread. The eccentricity of the "X axis" determines the minor diameter of the thread. By simply changing the "Z axis" travel direction either right or left-handed threads can be machined. But in each case the whirling ring always rotates in the same direction as the workpiece, it’s the direction of travel that yields the desired left or right hand threads.

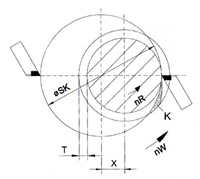

The cutting tools are mounted in the tool ring, and move relative to the workpiece. The chips generated from this cutting process are ideally comma-shaped, (see figure 2). Although whirling is an interrupted cutting process the smooth chip formation is such that hardened material to 65 HRc and brittle material can be cut, with either carbide, CBN (Cubic Boron Nitride) or with ceramic tools.

- nW Rotation of whirling tool

- T Depth adjustment

- nR Rotation of workpiece

- X Eccentricity

- SK Cutting circle

- K Comma shaped chip

Comparing Whirling with Milling

When cutting external threads, we first must look at the similarities between whirling and milling. A whirling ring has multiple cutting teeth similar to a milling cutter. Each cutting edge removes a certain amount of material during the noncontinuous cutting operation. But that’s where the similarities end.

Whirling has a more favorable cutting action, due to the gradual entry and exit of the insert cutting edges, allowing greater metal removal rates. This smooth cutting action reduces radial pressure, creating less stress on the workpiece and insert. Also tool life is significantly extended making the process even more cost effective (see figure 3).