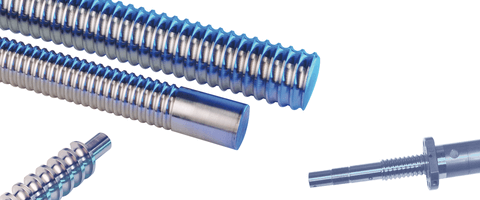

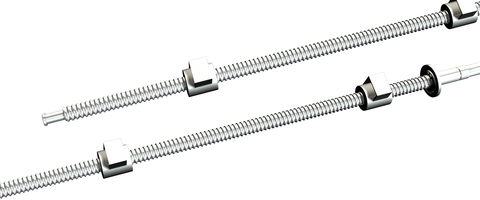

Saving energy and thereby costs plays an important role in many industries. In aviation, this is best realized by reducing weight. The use of hollow shafts in the drive, for example, offers substantial potential for lightweight construction. In opposite to traditional methods, with Leistritz whirling machines, the highest cutting volumes and a very high level of accuracy can be achieved – even when machining titanium materials. Our machining solutions also convince due to their high level of flexibility, which has great effects when manufacturing small batch sizes.